| Sign In | Join Free | My xxjcy.com |

|

- Home

- Products

- About Us

- Quality Control

- Contact Us

- Get Quotations

| Sign In | Join Free | My xxjcy.com |

|

Brand Name : Rvyuan

Certification : IEC/NEMA/JIS/RoHS/ISO

Place of Origin : China

Price : Negotiation

Payment Terms : Negotiation

MOQ : Different types with differet MOQ

Packaging Details : Spool with carton

Delivery Time : 2-15 workding days

Supply Ability : Satisfy your demand

Model Number : 0.012-0.8mm

Stock : Available

Insulation : UEW

Conductor Type : Round copper

Bond coat : Self adhesive layer

Size : 0.012-0.8mm

Certificates : ISO 9001-2000, ISO TS 16949, ISO 14001-2004, UL Approved, RoHS

0.012-0.8MM ENAMELED COPPER WIRE MAGNET WIRE FOR MOTOR WINDING

Enameled wire or magnet wire contains the following elements:

Conductor type: The conductor is the basic material of the enameled wire. Commonly used materials for conductors are copper, aluminum and Copper-silver alloy, copper-tin alloy, copper-nickel alloy, copper-zinc alloy and other alloy materials. Usually the resistance in an electronic component is determined by the conductor. The cross-sectional area and length of the conductor affect the resistance.

The type of insulating film: The insulating film is divided into single film and heavy film. Single film includes UEW, PEW, EIWHE AIW etc. Heavy film refers to an additional coating of nylon or self-adhesive paint on a single film.

The thickness of the coating is the thickness of the insulating paint on the conductor. The coating thickness is classified and defined by NEMA, MW1000, JISC3202, and IEC60317 standards. The thickness of the coating determines the pressure level of the enameled wire.

Thermal rating refers to the heat resistance level of the enameled wire, showing the temperature index, softening breakdown and thermal shock, etc. It is defined by the NEMA, MW1000, JISC3202, and IEC60317 standards. Thermal rating are 130, 155, 180, 200, 220, 240.

FEATURES AND BENEFITS:

Can be soldered without removal of coating,and easy to be dyed.

Small dielectric loss under high frequency apparatus and good pinhole test performace.

Apply to replays,micro-motors,transfomers,instrumentation and various kinds of electronic components and with for coils

APPLICATIONS:

Rotating machines

Power and Distribution Transformers

Alternators

Hermetic motors (for refrigeration and air conditioning equipment)

Control and Power supply Transformers

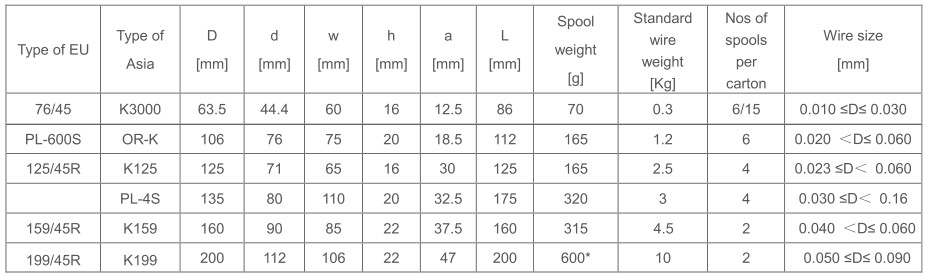

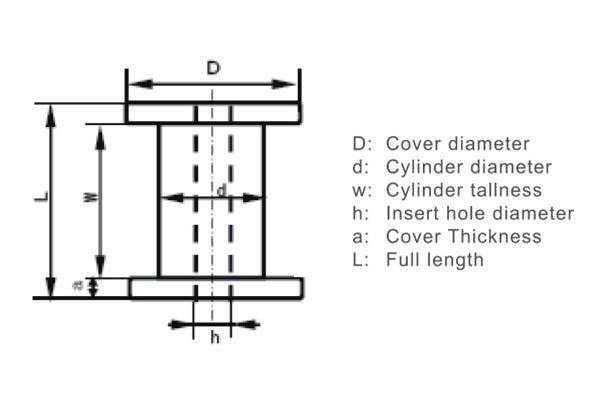

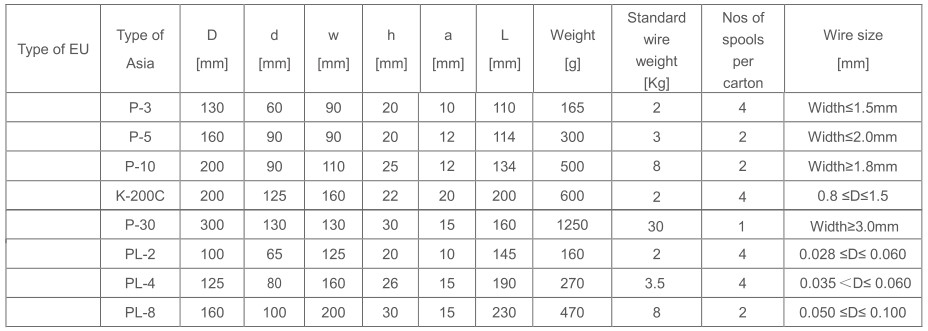

SPOOL SIZE

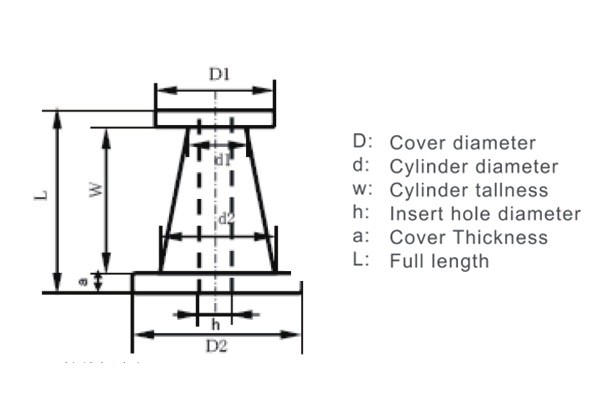

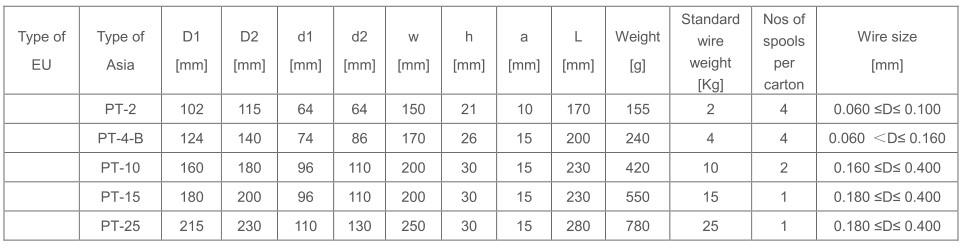

BICONICAL TYPE

CYLINDRICAL TYPE

TAPERED TYPE

SPECIFICATION:

| Diameter (mm) | Tolerance (mm) | Max Diameter | Min Film Thickness | Min breakdown voltage(20°C) | Conductor resistance ohm/m(20°C) | |||||||||

| Class1 | Class2 | Class3 | Class1 | Class2 | Class3 | Class1 | Class2 | Class3 | Min | Max | ||||

| 0.028 | -- | 0.034 | 0.038 | -- | -- | -- | -- | 170 | 325 | -- | 24.99 | 30.54 | ||

| 0.032 | -- | 0.039 | 0.043 | -- | -- | -- | -- | 190 | 375 | -- | 19.13 | 23.38 | ||

| 0.036 | -- | 0.044 | 0.049 | -- | -- | -- | -- | 225 | 425 | -- | 15.16 | 18.42 | ||

| 0.040 | -- | 0.049 | 0.054 | -- | -- | -- | -- | 250 | 475 | -- | 12.28 | 14.92 | ||

| 0.045 | -- | 0.055 | 0.061 | -- | -- | -- | -- | 275 | 550 | -- | 9.705 | 11.79 | ||

| 0.050 | -- | 0.06 | 0.066 | -- | -- | -- | -- | 300 | 600 | -- | 7.922 | 9.489 | ||

| 0.056 | -- | 0.067 | 0.074 | -- | -- | -- | -- | 325 | 650 | -- | 6.316 | 7.565 | ||

| 0.063 | 0.002 | 0.076 | 0.083 | -- | 0.007 | 0.012 | 0.018 | 375 | 700 | -- | 5.045 | 5.922 | ||

| 0.071 | 0.003 | 0.084 | 0.091 | 0.097 | 0.007 | 0.012 | 0.018 | 425 | 700 | -- | 3.941 | 4.747 | ||

| 0.080 | 0.003 | 0.094 | 0.101 | 0.108 | 0.007 | 0.014 | 0.020 | 425 | 850 | 1200 | 3.133 | 3.703 | ||

| 0.090 | 0.003 | 0.105 | 0.113 | 0.120 | 0.008 | 0.015 | 0.022 | 500 | 900 | 1300 | 2.495 | 2.900 | ||

| 0.100 | 0.003 | 0.117 | 0.125 | 0.132 | 0.008 | 0.016 | 0.023 | 500 | 950 | 1400 | 2.034 | 2.333 | ||

| 0.112 | 0.003 | 0.13 | 0.139 | 0.147 | 0.009 | 0.017 | 0.026 | 1300 | 2700 | 3900 | 1.632 | 1.848 | ||

| 0.125 | 0.003 | 0.144 | 0.154 | 0.163 | 0.010 | 0.019 | 0.028 | 1500 | 2800 | 4100 | 1.317 | 1.475 | ||

| 0.140 | 0.003 | 0.16 | 0.171 | 0.181 | 0.011 | 0.021 | 0.030 | 1600 | 3000 | 4200 | 1.055 | 1.170 | ||

| 0.160 | 0.003 | 0.182 | 0.194 | 0.205 | 0.012 | 0.023 | 0.033 | 1700 | 3200 | 4400 | 0.8122 | 0.8906 | ||

| 0.180 | 0.003 | 0.204 | 0.217 | 0.229 | 0.013 | 0.025 | 0.036 | 1700 | 3300 | 4700 | 0.6444 | 0.7007 | ||

| 0.200 | 0.003 | 0.226 | 0.239 | 0.252 | 0.014 | 0.027 | 0.039 | 1800 | 3500 | 5100 | 0.5237 | 0.5657 | ||

| 0.224 | 0.003 | 0.252 | 0.266 | 0.280 | 0.015 | 0.029 | 0.043 | 1900 | 3700 | 5200 | 0.4188 | 0.4495 | ||

| 0.250 | 0.004 | 0.281 | 0.297 | 0.312 | 0.017 | 0.032 | 0.048 | 2100 | 3900 | 5500 | 0.3345 | 0.3628 | ||

| 0.280 | 0.004 | 0.312 | 0.329 | 0.345 | 0.018 | 0.033 | 0.050 | 2200 | 4000 | 5800 | 0.2676 | 0.2882 | ||

| 0.315 | 0.004 | 0.349 | 0.367 | 0.384 | 0.019 | 0.035 | 0.053 | 2200 | 4100 | 6100 | 0.2121 | 0.227 | ||

| 0.355 | 0.004 | 0.392 | 0.411 | 0.428 | 0.02 | 0.038 | 0.057 | 2300 | 4300 | 6400 | 0.1674 | 0.1782 | ||

| 0.400 | 0.005 | 0.439 | 0.459 | 0.478 | 0.021 | 0.040 | 0.060 | 2300 | 4400 | 6600 | 0.1316 | 0.1407 | ||

| 0.450 | 0.005 | 0.491 | 0.513 | 0.533 | 0.022 | 0.042 | 0.064 | 2300 | 4400 | 6800 | 0.1042 | 0.1109 | ||

| 0.500 | 0.005 | 0.544 | 0.566 | 0.587 | 0.024 | 0.045 | 0.067 | 2400 | 4600 | 7000 | 0.08462 | 0.08959 | ||

|

|

0.012-0.8mm Magnet Wire Enameled Copper Wire For Motor Winding Images |